SIPs Self-Build House Kits

Designed

Manufactured

Delivered

Erected

Nationwide

07577 791 936

Frequently Asked Questions

1 - What are SIPS?

-

Structural Insulated Panels (SIPs) are a composite panel that can be utilised for wall and roof structures and are known as a good modern construction material. SIPs are the sheathing, framing and insulation all in one prefabricated panel

-

SIPs panels can be used in new structures as load bearing and non- load bearing walls

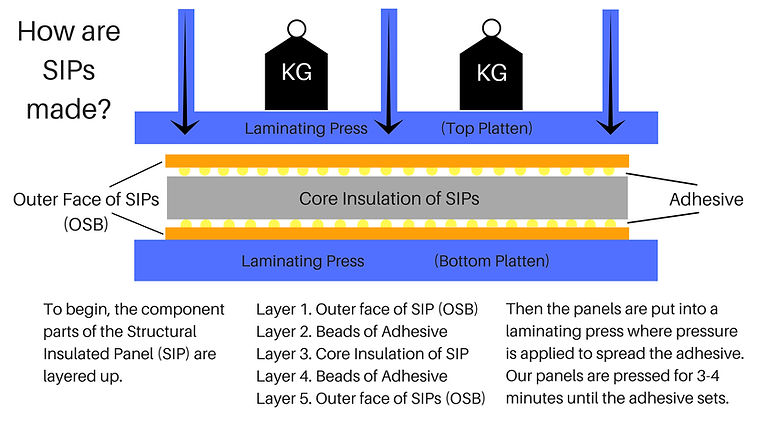

2 - How are SIPs made?

-

Typically, SIPs are made with Oriented Strand Board (OSB) faces; however, they can also be manufactured using other sheet materials such as Plywood, Cement Particle Board (CPB), and Magnesium Oxide Board

-

SIPs can be manufactured with different cores including: Expanded Polystyrene (EPS) Graphite Infused Polystyrene (Neopor EPS) Polyurethane (PUR) or Polyisocyanurate (PIR)

-

Eco SIPs Homes Structural Insulated Panels are manufactured using Neopor Graphite EPS, sandwiched between two structurally rated skins of Orientated Strand Board (OSB/3) that can provide continuous structural integrity and superior insulation within one component

3 - What is the fire performance of a SIP house?

-

When Eco SIPs Homes Structural Insulated Panels are used as part of a through wall build up they can achieve a fire resistance of up to 90 minutes meeting all current requirements for Building Regulations

4 - What type of buildings can SIPS be used for?

SIPs can be utilised in any construction project including

-

Residential

-

Leisure

-

Commercial

-

Education

-

Retail

-

Full structural envelopes

-

Infill panels within a steel, concrete or timber frame

5 - Why choose SIPs over traditional methods?

-

Installation time can be reduced up to 60% against tradition construction therefore reducing overall onsite costs due to reduced project management costs, scaffold hire, plant hire, welfare facilities and most importantly labour

-

Superior insulation provides improved energy efficiency and air tightness which reduces heating and cooling costs

-

Factory controlled manufacturing provides a consistent and accurate engineered product allowing for easier and precise installation

-

Offsite manufacture results in less waste on site

-

Panels can be built in to large format walls prior to site delivery therefore reducing installation time

-

Up to 7 times stronger when compared to timber frame construction

6 - What type of foundations are required for a SIPs building?

-

Any foundation method can be used with SIPS, however, the slab or other types of foundation should be level and square to allow for easy installation. For our garden rooms we use ground screws, these are supplied and iinstalled by https://stop-digging.co.uk/

7 - How do I get planning approval when using SIPs?

-

SIPs are an accepted form of construction and raise no issues when obtaining planning approval

8 - Is SIPs construction more expensive?

-

The initial, up-front cost of a SIPs build over traditional methods i.e. timber frame or brick and block, is typically slightly higher for the structural frame dependent on the type of the design

-

The overall cost is less, the savings in construction time, reduction of material wasted on site and improved energy efficiency of the building will bring significant savings, making a SIPS construction a long-term effective solution

9 - How much time can be saved building with SIPs?

-

The time savings over timber frame or traditional methods of construction can be significant if an experienced SIPs installer is undertaking the build (up to 65% less). The separate steps of timber framing, insulating and sheathing are eliminated due to the composite nature of SIPs

-

SIPs flexibility allows architects to design window and door apertures into the structural envelope reducing the need for traditional supports and lintels. Sips Panels are manufactured in the factory and once installed; SIPs are ready for interior and exterior finishing

10 – What kind of external finish can a SIPs building have?

-

External finishes are numerous and you can have many different types to suit your needs. You can have traditional cavity and brick or stone wall, render, brick slips, timber cladding, slate, copper, zinc, stainless standing seam, etc

11 - What is the durability of a SIPs building?

-

A building constructed with SIPs panels will have durability comparable to other forms of traditional construction. If the design of the structure follows best practice and the building is maintained and weather tight, a life of at least 60 years can be expected

12 - What is thermal bridging?

-

Thermal Bridging is the ability of external cold transfer to internal walls which can result in cold spots and damp. A thermal bridge/cold bridge is created when materials that are poor thermal insulators come into contact which allows heat to flow through the path created. SIPs panels have an insulated core which virtually eliminates thermal/cold bridging

-

Eco SIPs Homes Structural Insulated Panels can be joined together with the use of an insulated SIPS spline which provides a continuous EPS core through the walls and roof of the building. This greatly reduces the thermal bridging and improves the efficiency of the building compared to timber frame studs.

13 - Is air tightness important?

-

Yes, air tightness is crucial in eliminating heat loss from a building. The superior air tightness of SIPs and the jointing method can create an airtight structure that meets all the new Building Regulation requirements

-

The SIPs system is so effective that positive ventilation should be considered which can be linked to a heat recovery system and further reduce energy costs. See our section on MVHR

14 - Are independent warranties available for a SIPs building?

-

Yes, warranties for buildings constructed from SIPs are available from the leading companies who offer structural defects warranties. Our system has third party certification and is approved by LABC, Premier, NHBC and others

-

All the major banks and lenders can offer mortgages on SIPs buildings.

We can offer further advice on this if required and put you in contact with self-build mortgage advisors

15 - Is SIPs construction considered to be environmentally sustainable?

-

Yes, Eco SIPs Homes Structural Insulated Panels are manufactured using OSB sheathing and timber products from sustainably sourced and managed plantations. All our engineered wood products have PEFC chain of custody certification

-

Timber is considered a sustainable building material because it is derived from a renewable source and has low embodied energy

-

The graphite EPS core in our Structural Insulated Panels has a BRE green guide rating of A+

-

Our insulation is CFC and HCFC free

-

It has zero Ozone Depletion Potential

-

It has a (GWP) Global Warming Potential rating of zero

16 - What are U-Values?

-

U-Value is the measurement of heat flow through any given combination of materials, air layers and air spaces. The lower the U-Value, the more slowly the transfer of heats in and out of a building and the better the insulating quality

17 - What are the U-Values that can be achieved using SIPs?

-

Our standard wall panels can achieve u-values from 0.21 down to 0.13 (without any additional insulation). Look at our product data sheet in our technical section for more details on specific panels

18 - Can SIPs be used for party walls between dwellings?

-

Yes, our panels have been used successfully in party wall construction, achieving a 59dB reduction with 25mm mineral wool and plasterboard plank to either side

Did you find what you were looking for?

If not, you can ask us a question here